SMT AOI Machine: Revolutionizing SMT Inspection with AI Technology

In the dynamic world of Surface Mount Technology (SMT), precision and efficiency are paramount. Manufacturers worldwide seek inspection solutions that enhance accuracy and streamline production processes. Enter SMT AOI AI Inspection Technology – an innovative solution that combines cutting-edge artificial intelligence algorithms with advanced inspection capabilities.

Improved Accuracy and Consistency with Advanced AI Algorithms

Traditional inspection methods often struggle with subtle defects. Our SMT AOI Machine utilizes advanced AI algorithms and four-color lighting with light detection for a thorough inspection, ensuring precise defect detection.

Benefits of AI-powered Inspection Algorithms

- Enhanced Accuracy: Detect even the most minor defects and inconsistencies in component placement or soldering.

- Reduced Variability: Achieve consistent results with a stability index (GR&R < 10% @ 6 Sigma) and test deviation accuracy of less than ±0.25mm.

Simplifying Operations with Intuitive AI Integration

Complex programming is a thing of the past. Our AI-driven SMT AOI Machine simplifies operations with one-click programming and intuitive AI algorithms. Users can create and deploy PCB inspection programs quickly, minimizing downtime and maximizing productivity.

Advantages of AI-based User Interface

- One-Click Programming: Eliminate hours of programming with a user-friendly interface.

- Quick Program Deployment: Easily create and deploy PCB inspection programs, streamlining operations.

Intelligent AI AOI Applications in Various Manufacturing Scenarios

In the realm of modern manufacturing, the integration of intelligent AI AOI (Automated Optical Inspection) systems has enhanced quality control across different production lines. Let's explore how these systems are utilized in three key manufacturing scenarios: SMT production lines, DIP production lines, and PCBA coating lines, along with their respective roles and advantages.

Enhancing Quality Control in SMT Production Lines

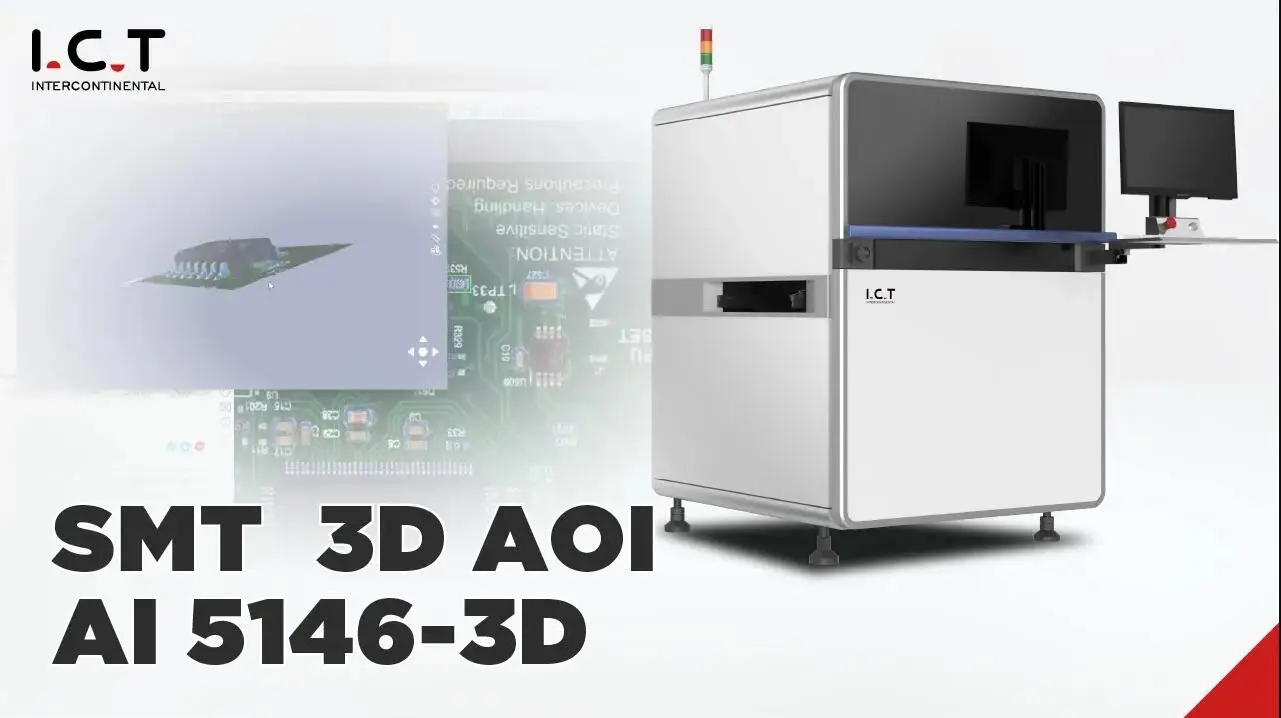

Our SMT AOI Machine models, I.C.T-V8 (Offline) and I.C.T AI-5146 (Online), ensure the quality and reliability of surface-mounted components on PCBs (Printed Circuit Boards).

Benefits of AI AOI in SMT Production

- Real-Time Inspection: High-speed imaging and processing enable swift identification and rectification of issues during production.

- Reduced Downtime: Early defect detection minimizes faulty PCBs progressing down the line, saving time and materials.

- Improved First-Pass Yield: Enhance PCB yield by identifying and correcting defects early in the production process.

Ensuring Quality in DIP Production Lines

Our DIP AOI Inspection Machine range, including AI-4026 (Before THT Soldering), AI-4540 (After THT Soldering), and AI-5146W (Double-sided), guarantees the quality of through-hole components and solder joints.

Advantages of AI AOI in DIP Production

- Comprehensive Inspection: Inspect through-hole components and solder joints for proper insertion, alignment, and soldering quality.

- Tailored Solutions: Address specific needs with pre and post-THT soldering inspection options.

- High-Performance Inspection: Achieve efficient and reliable inspection with high-speed imaging and processing.

Optimizing PCBA Coating Lines

I.C.T PCBA Coating Line Online AOI AI-5146C ensures the uniformity and integrity of conformal coatings applied to PCBs for environmental protection.

Benefits of AI AOI in PCBA Coating Lines

- Uniform Coating Inspection: Verify consistent coating application for optimal protection.

- Defect Detection: Identify various coating defects like bubbles or cracks, ensuring assembly reliability.

- Streamlined Process: Seamless integration into coating lines enhances efficiency and reduces defect risks.

Conclusion

In today's competitive landscape, SMT manufacturers require exceptional quality and speed. Our SMT AOI Machine with AI inspection technology sets a new benchmark for precision, consistency, and user experience. This comprehensive solution tackles industry challenges and propels manufacturing processes forward.

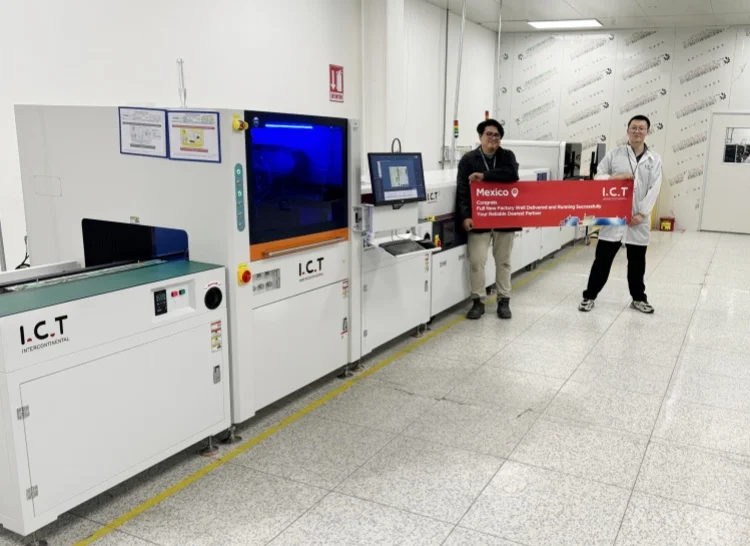

I.C.T.'s commitment to customer satisfaction

I.C.T offers comprehensive after-sales support, ensuring prompt assistance and maintenance services globally.

Contact us today to explore how our SMT AOI Machine with AI technology can elevate your production capabilities.