I.C.T Lead-free Wave Soldering Machine W3

Min. Order : 1

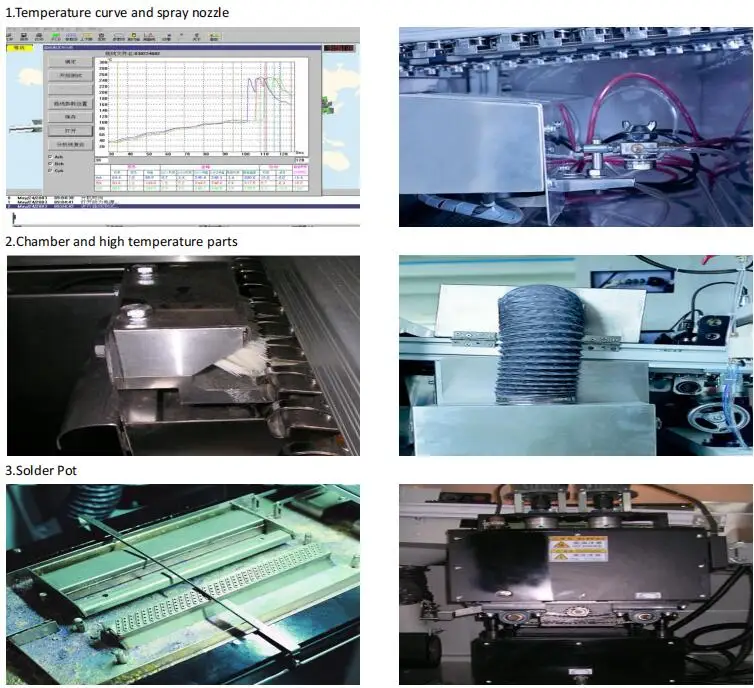

Brief introduction : THT soldering equipment wave soldering machine I.C.T lead-free wave soldering machine with 3 preheating zones and 2 wave can achieve good welding effects.

Min. Order : 1

Brief introduction : THT soldering equipment wave soldering machine I.C.T lead-free wave soldering machine with 3 preheating zones and 2 wave can achieve good welding effects.

I.C.T W series lead-free wave soldering machine,after many years market testing, is I.C.T’s mature product, W series lead-free wave soldering machine has long-term positive feedback from customers. Its unparalleled heating performance and temperature control system meet the requirements of various welding processes, especially energy saving design has been a leading-edge product advantage, maximum reducing the using cost for customers.

TOP Advantage:

Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to understand, easy to learn, easy to maintain.

Expertise: learn imported reflow oven’s advanced design concepts, and the components are using imported top brands.

Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

Stable: mature software, hardware and top production processes ensures stability of each equipment.

I.C.T is the SMT machine supplier with professional 25-year-experienced sales and after sales team, providing SMT solutions including SMT stencil printer, pick and place machine, reflow oven, SMT line and wave soldering machine.

We also is the partner of JUKI pick and place machine and Hanwha/Samsung pick and place machine, can provide the best SMT technical services and accessories support for JUKI, HANWHA/SAMSUNG, YAMAHA, PANASONIC brands.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

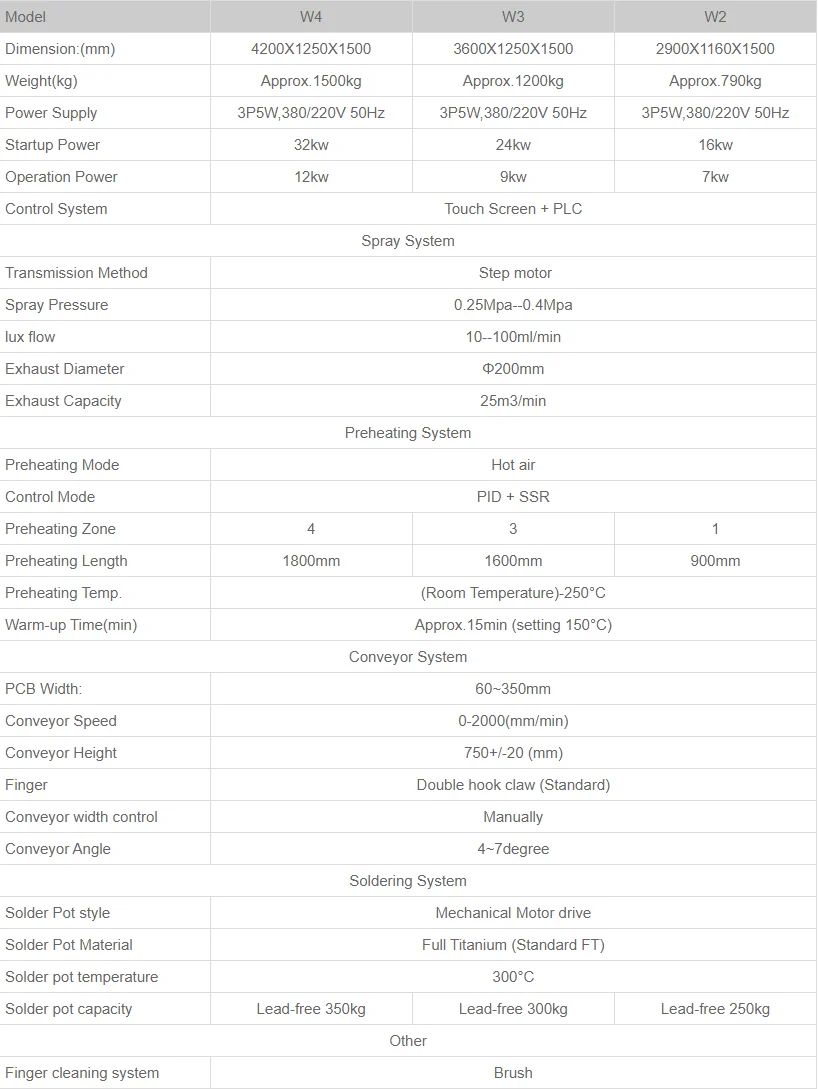

| Model | W2 | W3 | W4 |

| Dimension(mm) |

2900X1160X1500 |

3600X1250X1500 |

4200X1250X1500 |

| Weight(kg) |

Approx.790kg | Approx.1200kg | Approx.1500kg |

| Power Supply |

3P5W,380/220V 50Hz |

3P5W,380/220V 50Hz |

3P5W,380/220V 50Hz |

| Startup Power |

16kw | 24kw | 32kw |

| Operation Power |

7kw | 9kw | 12kw |

| Control System |

PLC | ||

| Spray System |

|||

| Transmission Method |

Step motor |

||

| Spray Pressure |

0.25Mpa--0.4Mpa |

||

| Flux flow |

10--100ml/min |

||

| Exhaust Diameter |

Φ200mm |

||

| Exhaust Capacity |

25m3/min |

||

| Preheating System |

|||

| Preheating Mode |

Hot air |

||

| Control Mode |

PID + SSR |

||

| Preheating Zone |

2 | 3 | 4 |

| Preheating Length |

1200mm | 1600mm | 1800mm |

| Preheating Temp. |

(Room Temperature)-250°C |

||

| Warm-up Time(min) |

Approx.15min (setting 150°C) |

||

| Conveyor System |

|||

| PCB Size:LxW(mm) |

Min:80x60mm; Max:400x300mm |

||

| Conveyor Speed |

0-2000(mm/min) |

||

| Conveyor Height |

750+/-20 (mm) |

||

| Finger |

Double hook claw (Standard) |

||

| Conveyor width control |

Manually |

||

| Conveyor Angle |

4~7 degree |

||

| Soldering System |

|||

| Solder Pot style |

Mechanical Motor drive |

||

| Solder Pot Material |

Full Titanium (Standard FT) |

||

| Solder pot temperature |

300°C |

||

| Solder pot capacity |

Lead-free 200kg |

Lead-free 300kg |

Lead-free 350kg |