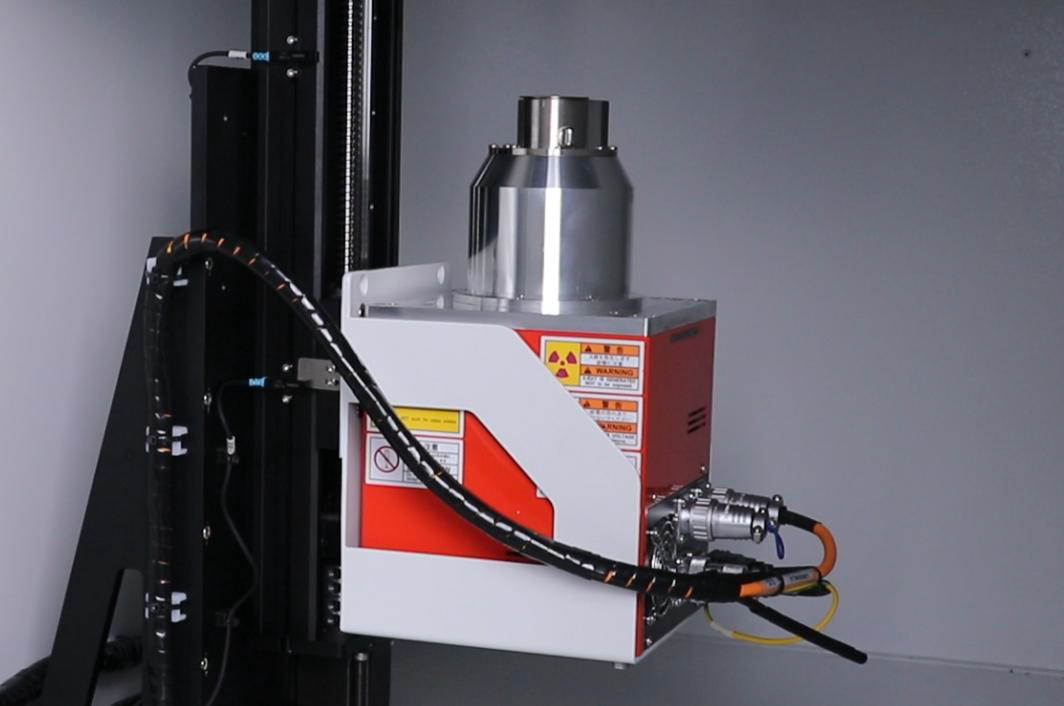

I.C.T X-7900 SMT Offline X-ray Inspection System for PCBs

Min. Order : 1

Payment Type : L/C, T/T

Incoterm : FOB,CFR,CIF

Delivery Time : 35 working day

Brief introduction : I.C.T X-7900 electronic semiconductor testing equipment can be used to detect integrated circuit chip semiconductors, such as BGA, IGBT, flip-chip and PCBA component welding.