DIP On-line Dual Side Online AOI

Min. Order : 1

Payment Type : L/C,T/T

Incoterm : FOB,CFR,CIF

Delivery Time : 35 working days

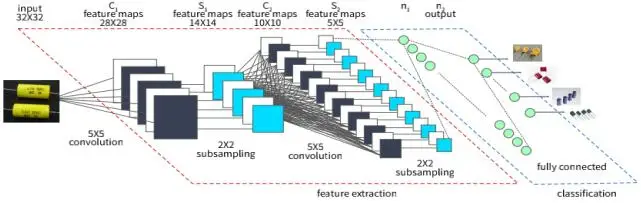

Brief introduction : I.C.T DIP dual side AOI captures board image in real time by high precision color industrial camera. Adopt Convolutional Neural Network (CNN) algorithm to process images. Judge defects of components intelligently.