SMT Nozzle Cleaning Machine I.C.T-24/36

Brief introduction : SMT Nozzle Cleaning Machine I.C.T-24/36

Brief introduction : SMT Nozzle Cleaning Machine I.C.T-24/36

❙ Introduce of SMT Nozzle Cleaning Machine

With it special mechanical design,I.C.T-24 using the hydrodynamic water fragmentation, producing very fine water mist, with the speed of sound (V = 360m/s) to form a strong momentum jet to the nozzle, nozzle for cleaning at the top of the formation of a continuous field, crushing the internal surface of the dirt (the nozzle will not be damaged because of its independent device),during the cleaning process the used cleaning water (deionized water or distilled water)automatic direct emissions.

Features:

1.Clean 24 nozzles in one time, quicker and more efficient Precautions:

1.Never open the inlet cover of the water tank during cleaning process, water will be spray out with high water pressure. 2.Please use DI water or distilled water,never use mineral water or tap water.

3.Blow and make the remain water in the cleaning tank by using air gun after cleaning.

4.Please check whether nozzles is set right on to the jig hole each time.

5.Please aviod hit the stretch cyliner jet head when placing nozzle jig onto the rotation plate; the concentricity of the jet heads and nozzle jig is adjusted and set by beam sensor in our factory, if hit is not serious, it will not affect the concentricity; if hit seriously and affect the concentricity, please contact us or our agent for right adjust method.

6.Please replace the air filter each year. The regular filter replace time is 1 year but it supple sources of factory; If filter turns yellow or black, it must be replaced right now.

❙ Specification of PCBA Cleaning Machine

| Item | I.C.T-24/36 |

| Air supply |

0.5~0.7Mpa |

| Power supply |

AC220V,1A |

| Clean liquid |

Purified water or DI water |

| Clean time |

2~3min |

| Dry time |

1~3min |

| Jet pressure | ≤0.55Mpa |

| Water consumption |

≤150cc/hour |

| Nozzle range |

Min 01005~Max inner diameter ¢2.0mm |

| Jig Spec |

I.C.T-24:Small nozzle 24 holes /big nozzle 12 holes I.C.T-36:Small nozzle 36 holes /big nozzle 12 holes |

| Machine size |

L665 x W555 x H475(mm) |

| Machine weight |

40KG |

Click Here Get More Informaion!

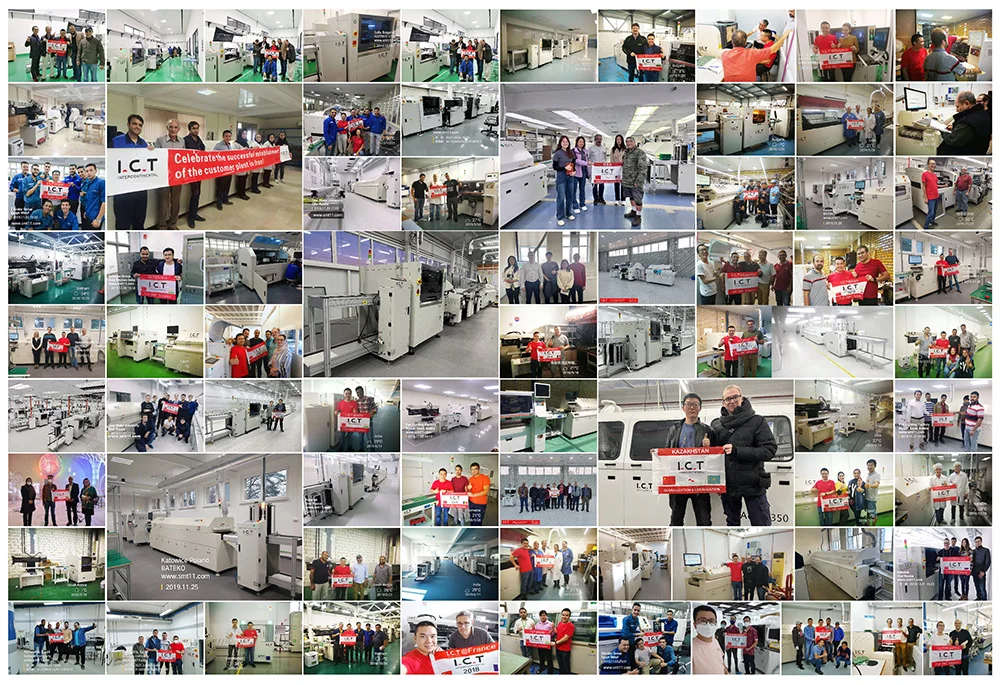

❙ I.C.T Customer Factory

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

Click Here Get More Informaion!

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ I.C.T SMT Nozzle Cleaning Machine