CASE

Innovative SMT Solution for Russian Underwater Drones by I.C.T

Innovative SMT Solution for Russian Underwater Drones by I.C.T In April 2022, a Russian IT and robotics development company reached out to I.C.T with an inquiry: they were in need of an SMT Production Line for their latest project, Underwater Drones. We quickly established a strong relationship and embarked on our first collaboration. Recognizing the significance of the project, our I.C.T engineers engaged in active discussions with the client to assess the specific requirements of the product. Taking into consideration the provided PCB motherboard information and their projected future production capacity, we offered a turnkey SMT Solution for the Underwater Drones. The selected production line equipment included Full-auto Solder Paste Printer Machine, Online SMT SPI, SMT Pick and Place Machine, Reflow Oven Lyra622, Online SMT AOI, NG/OK Unloader Machine, PCB Conveyors, and more.

Adding PCB Dispenser and SMT Depanelizer to Computer PCBA Production Line

❙ Malta ❙ Cooperation time - 2023 year ❙ Project - Computer PCBA ❙ Solutions - Adding PCB Dispensing Machine and SMT Routing Machine A local computer and motherboard PCBA manufacturer in Malta purchased our SMT Dispensing Machine and PCB Routing Machine to enhance their computer production line. Our engineer Andy visited the customer's factory on May 25 to install, commission, and provide technical support and training. The custom solution seamlessly integrated the machines into the existing production line, meeting the customer's requirements for smooth operation and increased productivity. The equipment was successfully delivered to the customer on May 26, 2023. Unsure about the right solution for your factory setup? Our team of engineers can offer expert recommendations tailored to your needs. phone: +86 13670124230 , email: info@smt11.com

Successful Delivery of SMT Production Line in the Greece Security Applications

❙ Greece ❙ Cooperation time - 2022 year ❙ Project - Security Applications ❙ Solutions - Full-auto SMT Line In the field of security applications, an efficient and reliable production line is crucial for manufacturing high-quality products. On June 1, 2023, , we successfully delivered a complete SMT production line to a leading manufacturer of security applications in Greece. This production line includes key equipment such as SMT Loader, Automatic SMT Printer, Hanwha Pick and Place Machine, Reflow Oven, NGOK PCB Unloader. I.C.T provide a comprehensive production solution for the customer.

Denmark Semi-auto LED Prodcution Line

❙ Denmark ❙ Cooperation time - 2022 year ❙ Project - LED LIGHT SIGNS ❙ Solutions - Semi-auto LED Prodcution Line In 2022, I.C.T successfully delivered a complete semi-auto SMT LED Production Line to a professional manufacturer of waterproof and energy-saving lighting signs in Denmark. The production line included equipment such as a 1.8m semi-auto Solder Paste Printer, high speed LED Pick and Place Machine, 8-zone Reflow Soldering Oven, and 2m SMT Conveyor. After the equipment arrived at the customer's factory, we provided online technical support, and the customer quickly began production and achieved smooth operation. On June 5, 2023, our engineer Andy visited the customer's factory to provide comprehensive SMT technical support. This visit further consolidated and extended our successful case of delivering a complete semi-automatic SMT LED production line in 2022.

LED LENS Project Successfully Delivered- SMT Production Line

LED LENS Project Successfully Delivered In this successful Case, we provided a brand new SMT Production Line tailored specifically for LED lens production to our Malaysian customer. The SMT production line equipment is a comprehensive and efficient solution, including a semi-auto printer, SMT conveyor system, an online LED LENS dispensing machine, a Samsung pick and place machine, a Bowl feeder, a Samsung original feeder, an 8-zone reflow soldering machine, and a cooling conveyor, among other key components. The integration of these devices offers our client a highly intelligent and flexible production line, enabling them to meet the diverse production requirements for different LED lens products. Our expert I.C.T engineer, Lucas, traveled to Malaysia on July 15th to conduct on-site installation and machine debugging, ensuring that the equipment was installed accurately and guaranteeing the smooth operation of the production line. In addition to the machine installation and debugging, Lucas provided comprehensive training to the client's operators, enabling them to proficiently utilize this advanced SMT production line. The training covered equipment operation, maintenance, troubleshooting, and other aspects, empowering the client's team to grasp the essentials quickly, ensuring efficient production in the future. As a professional content provider in the SMT industry, I.C.T will continue to offer the highest quality SMT Solutions and services to our global clients. We look forward to collaborating with more clients in the future.

LED Lighting SMT Line in Finland

❙ Finland ❙ Cooperation time - 2023 year ❙ Project - LED Lighting ❙ Solutions - Automatic SMT LED Production Line We have recently successfully delivered an advanced Automatic LED Lighting Production Line to our collaboration partner in Finland. The construction of this LED Production Line includes a series of equipment such as Vacuum SMT Loader, Full-auto SMT Stencil Printer, SAMSUNG Pick and Place Machine, Reflow Soldering Oven,SMT Conveyor and Cooling Vertical PCB Buffer. Our senior SMT engineer traveled to the customer factory on May 11th to oversee the establishment of the new SMT factory and provided professional technical support. The project was completed smoothly on May 24th and is now operating normally. If you also need to establish a factory but are uncertain about the suitable solution for your needs, our team of engineers can provide professional recommendations. You can contact us by phone: +86 13670124230 or directly through email: info@smt11.com ❙ Finland Customer Video

Full-auto LED LENS Production Line in Poland

Full-auto LED LENS Production Line in Poland Lena Lighting S.A., a leading high-quality lighting manufacturer from Poland, is making its mark on 70 markets worldwide. Established in 1989, Lena Lighting S.A. has garnered great appreciation, particularly in Western Europe and the Scandinavian Peninsula, where they are known for their professionalism and high-quality products. In 2021, they partnered with us, ICT, to acquire a fully automated LED lens SMT production line. To meet their specific requirements, our engineers devised a comprehensive plan for Lena Lighting S.A., which includes the installation of the Vacuum Magazine SMT Loader, Full-auto SMT Printer P6561, two SM481Plus Pick and Place Machine, I.C.T. 10 zones Reflow Oven Lyra733, Online SMT SPI, Online Dispensing Machine, Conveyors, and more.

LED Digital Billboards Production Line in U.S

LED Digital Billboards Production Line in U.S In 2017, when CIRRUS built their new factory in New Hampshire, United States, they reached out to our company, ICT. Initially, they purchased some SMT magazines from us. As their market expanded, their needs grew, and they subsequently purchased SMT Handling Machine, traceability devices, and laser marking machines from us. Recently, they placed an order for a PCBA coating production line, which includes the following components: PCB Coating machine, Loader and Unloader, UV Curing Oven, SMT Conveyors, etc. We customized this PCBA coating line specifically for CIRRUS to meet their requirements for high quality, efficiency, and reliability. Our partnership with CIRRUS has always been built on mutual trust and shared growth. We are committed to providing them with advanced solutions and assisting them in maintaining a leading position in the digital billboard industry.

LED TV SMT Production Line in Algeria

In December 2020, a well-known local home appliance company in Algeria reached out to us. They have their own television brand in Algeria and North Africa and needed an SMT production line for manufacturing LED TV backlight strips. I.C.T. technical engineers customized two SMT production lines for their specific product requirements. One production line was dedicated to LED TV Production Line, while the other was designed for LED lens manufacturing. Includes full-auto PCB Printer 1.2m, Pick and Place Machine, Reflow Oven L Series, Translational Vacuum Loader, PCB Magazine Unloader, SMT Barcode Inkjet Printer, 1.2 M Online Jet Dispensing Machine, UV Curing Oven U2 and Multi Blades LED Separator etc. This partnership with another LED TV collaborator in Algeria began in 2017. ❙ Customer Feedback and SMT Assembly Line Video

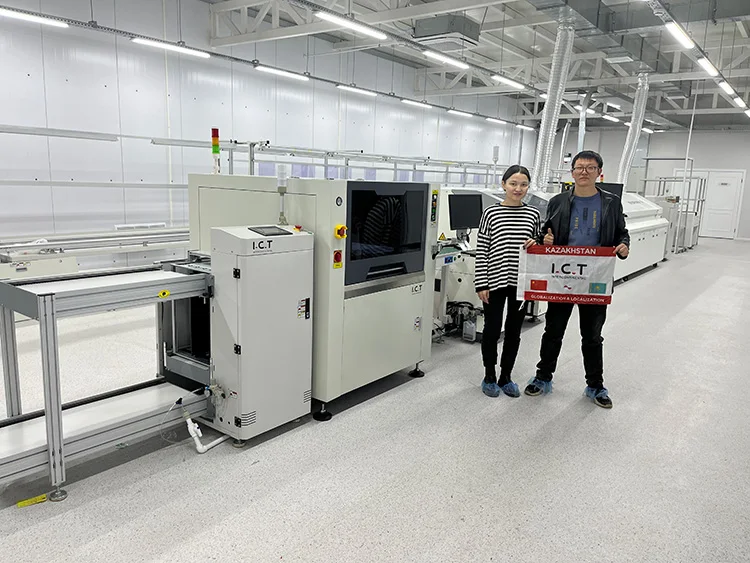

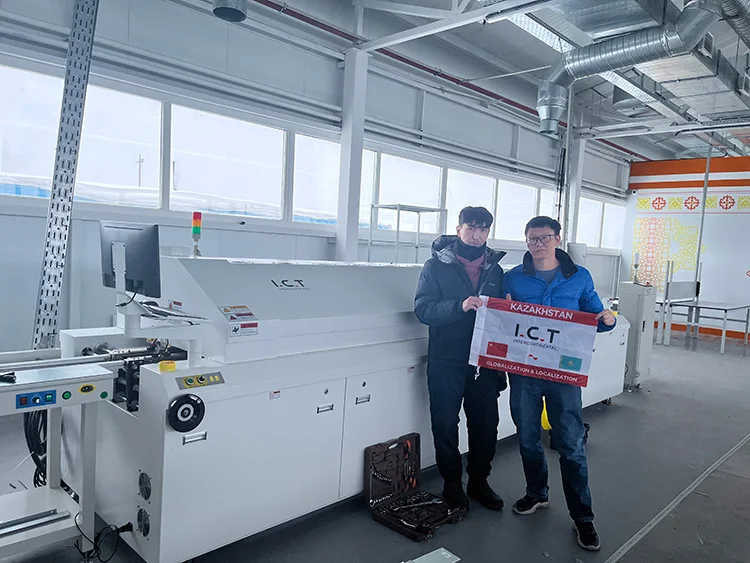

JUKI Full-auto SMT Line of Kazakhstan Partner

JUKI Full-auto SMT Line of Kazakhstan Partner In 2021, when this customer was planning to expand their factory, they contacted I.C.T. The customer discussed their project with us, which involved the production of communication industry products such as two-way radios and smart GPS wearable devices. Through active communication between our professional engineers and the customer, taking into account their future production capacity, we customized suitable full-automatic JUKI SMT Line and DIP Line for the customer. This included equipment such as solder paste mixer, SMT Stencil Printer, SMT PCB loader/unloader, JUKI Pick and Place Machine, L8 reflow oven, PCB conveyors, DIP insertion line, W2 Wave Soldering Machine, wave loader, wave unloader, belt assembly line, and offline selective soldering machine. In February 2023, our engineers arrived in Kazakhstan to provide comprehensive technical support to the customer.

Smart Home Product Full-auto JUKI SMT Line

Smart Home Product Full-auto JUKI SMT Line In 2018, our Russian client reached out to us for the first time and in 2019, they purchased our full-automatic SMT Production Line and DIP line equipment for educational purposes within their university, aiming to train more SMT engineers. In 2022, after conducting market research in Kazakhstan, they decided to establish a new factory in the region for the production of smart home products. They also approached the I.C.T team to discuss this new case. Considering the client's requirements and future development strategy, we provided them with a turnkey SMT solution tailored specifically to their needs. The equipment includes, but is not limited to, SMT PCB loader unloader, full-auto PCB printer, 2 JUKI RS-1R chip mounter (Double sides), PCB Reflow Oven, PCB conveyor, automatic insertion line, DIP wave soldering machine, wave loader, wave unloader, etc.

Philippines - SMT Customer

I.C.T Customized Reflow Soldering Oven - Philippines I.C.T high quality customized Reflow Oven, reflow soldering, reflow soldering oven, SMT reflow oven for Philippines customer factory. we provide better service and quality. Customers in Philippines are professional electronic equipment manufacturers. Since 2018, they have cooperated with I.C.T team. I.C.T provides customers with customized reflow soldering oven to produce motors. I.C.T engineers help install and do the training reflow soldering oven operation. They provide professional after-sales service for customers. Customers recognize the I.C.T team. ❙ Video for Reflow Oven