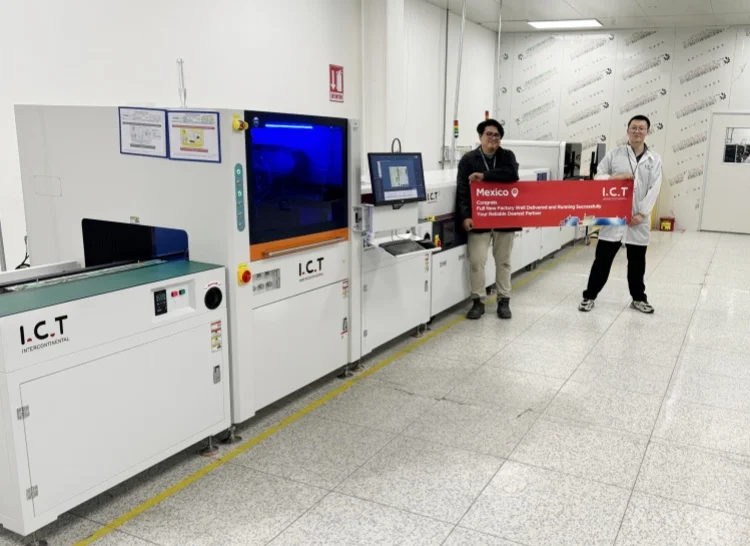

New Energy Automotive: I.C.T.'s Conformal Coating Line in Mexico

This article explores I.C.T.'s role in empowering a new energy automotive manufacturer in Mexico through the installation and technical support of a conformal coating line.

Conformal Coating Line Technical Support

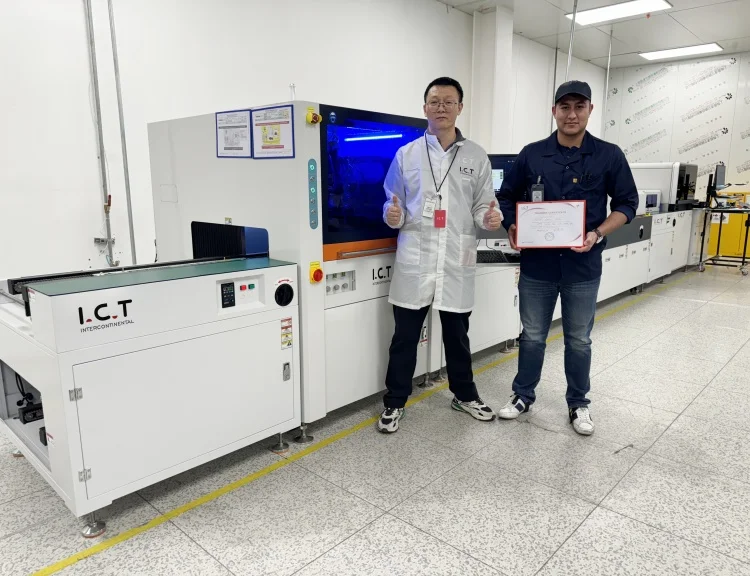

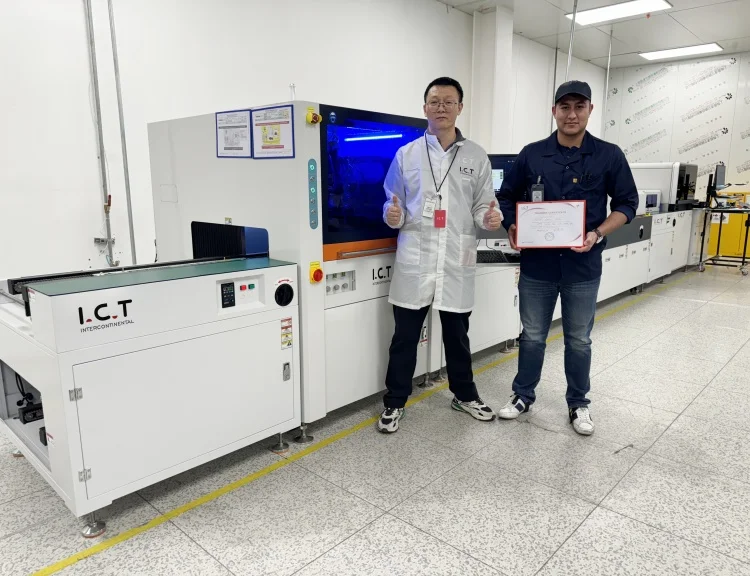

In the ever-evolving world of electronics manufacturing, Surface-mount technology (SMT) applications play a crucial role. As a leading company in this field, I.C.T has consistently delivered innovative solutions, including conformal coating lines, to its global clients. Recently, one of our experienced engineers, Andy, traveled to Mexico to provide technical support for a customer's new conformal coating line.

Conformal Coating Line Technical Support Process and Background

In April 2024, I.C.T. dispatched seasoned engineer Andy to Mexico to provide comprehensive technical support for a customer's newly acquired conformal coating line. Andy's mission encompassed several key tasks:

- Equipment Installation and Calibration: Ensuring the precise installation and calibration of all equipment within the conformal coating line.

- Operator Training: Providing thorough training to the customer's engineers on the safe and efficient operation of the conformal coating line.

- Maintenance Guidance: Equipping the customer's team with the knowledge and skills necessary for proper equipment maintenance, minimizing downtime and ensuring optimal performance.

Through these efforts, Andy ensured the seamless integration of the conformal coating line into the customer's production process and laid the foundation for optimal performance.

Customer Business Overview

The Mexican client specializes in contract manufacturing, producing a variety of electronic products. Their core business includes:

- Servers

- Computer Motherboards

- Components for New Energy Vehicles:

- Power Boards

- Battery Interconnect Boards

- Control Panels

Their growing involvement in the new energy vehicle sector necessitated a reliable solution for protecting these critical electronic components. They sought a three-proof coating production line, specifically a conformal coating line, from I.C.T. to enhance the durability and reliability of their products in harsh environments.

Introduction to the I.C.T. Conformal Coating Line

The conformal coating line equipment purchased by the Mexican client from I.C.T. boasts a range of advanced features, designed to deliver precise, efficient, and high-quality coating applications. Here's a breakdown of the key components:

- I.C.T-T650 Online PCBA Coating Machine: This machine offers exceptional precision and efficiency in applying the conformal coating material.

- I.C.T-AI-5146C Online Coating AOI (Automated Optical Inspection): This integrated system ensures accurate quality control by meticulously inspecting the coated surfaces for any defects.

- I.C.T-IR3 Infrared Curing Oven: This oven provides rapid and uniform curing of the applied conformal coating, guaranteeing optimal adhesion and long-lasting protection for the electronic components.

In addition to these core components, the conformal coating line also includes a range of complementary peripheral devices. Together, these seamlessly integrated components form a complete and efficient coating solution for the client's production needs.

Achievements and Impacts of Technical Support

The successful installation and commissioning of the conformal coating line equipment, coupled with the effective training provided by Andy, has had a significant impact on the client's production process and product quality. Here are some of the key achievements:

- Increased Production Efficiency and Throughput: The high-performance conformal coating line has significantly improved the client's production capacity, allowing them to manufacture products faster and meet growing demands.

- Reduced Coating Defects: The precise application and automated inspection capabilities of the line have minimized coating defects, leading to higher-quality products.

- Enhanced Customer Satisfaction and Competitiveness: The improved production efficiency and product quality have resulted in increased customer satisfaction and a stronger competitive edge for the client in the market.

- Empowered Workforce: The training provided by Andy has equipped the client's engineers with the skills and knowledge to operate and maintain the conformal coating line independently. This reduces reliance on external support and minimizes downtime, further enhancing overall operational efficiency.

By leveraging I.C.T.'s expertise in conformal coating line solutions and technical support, the Mexican client has successfully streamlined their production process and elevated the quality of their new energy automotive components.