1. Application of SMT Production Line and DIP Production Line

With the continuous development of technology, intelligent security products such as security monitors, access control systems, and smart locks have become an indispensable part of modern society. These products are increasingly widely used in daily life, making the quality and stability of products particularly important. In the field of security, SMT equipment and DIP equipment play an important role in the production process, ensuring the quality and performance stability of products, improving production efficiency and production benefits, and facilitating the maintenance and replacement of components to provide users with a better user experience.

SMT equipment is mainly used for the placement of electronic components, including chips, resistors, capacitors, diodes, and other components. In the security field, the basic SMT process and scheme are as follows

2. SMT Process

Solder Paste (Red Glue) Printing --> Components Placement --> Reflow Soldering --> AOI Optical Inspection

3. Entry-level SMT Production Line Solution for Security Cameras

1 operator to oversee the entire production line, 1 assistant, totaling 2 personnel.

- PCB Conveyor

- Reflow Soldering Oven (6-8 zones)

- Automatic PCB Unloader

- Off-line SMT AOI

4. DIP Process

5. Entry-level DIP Production Line Solution for Security Cameras

Personnel are adjusted according to the product, 3-15 people

- 6m Insertion Line

- Wave Loader

- Lead-free Wave Soldering Machine

- Wave Unloader

- 6m Belt Assembly Line

DIP production line equipment is mainly used for the fixation and connection of electronic components, including chips, resistors, capacitors, diodes, and other components.

We have matched this economical DIP production line with: 2.5m insertion line, wave soldering, and assembly line. The personnel configuration can be adjusted according to the product, usually 3-15 people.

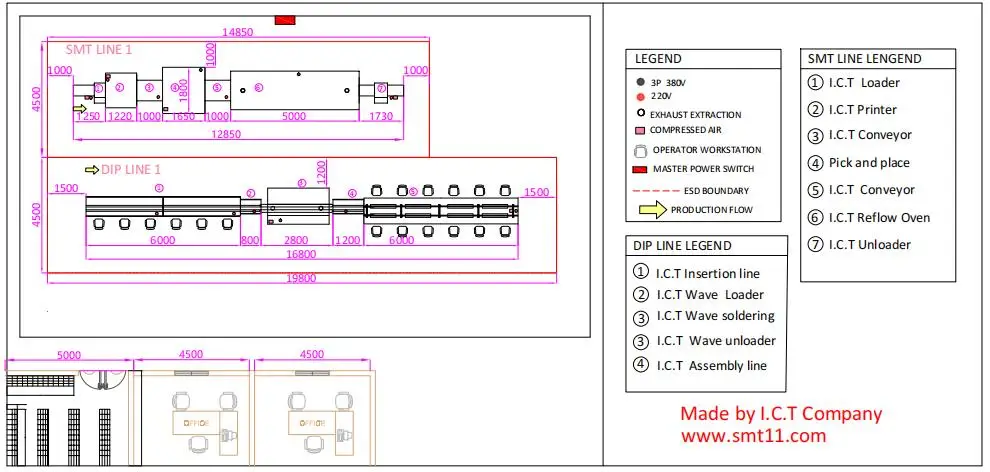

6. SMT Production Line and DIP Line Layout

7. SMT Solution Data

| SMT | Capacity Evaluation | 1 set pick and place machine; production capacity 20000-25000CHIP/H | ||||

| Total Power | 59.5 KW | Operating Power | 14.5KW | |||

| Applicable Product | SMD components within 50pcs, 0201-42mm, max PCB width 350mm |

|||||

| DIP | Capacity Evaluation | Calculated based on the number of componens and the operators | ||||

| Total Power | 16.8 KW |

Operating Power | 5.8 KW | |||

| Applicable Product | Low capacity requirements or simple products, Max PCB width 350mm | |||||

| SMT+ DIP |

Workshop Size | L20m x W15m , total area 300 ㎡ | ||||

The SMT placement equipment and DIP equipment we provide can be efficiently applied in the field of security products. If you want to develop a security product production line, such as monitors, access control, smart locks, alarm systems, and other products, our engineering team can provide you with a one-stop SMT solution to meet your needs. Contact us immediately and let us work together to realize your security product manufacturing project.

8. Recent Customer Case Studies

Our long-term partner in Kazakhstan, Russia, began cooperation with us in 2019. They purchased a complete automatic JUKI SMT production line and DIP production line at I.C.T for training and outputting excellent engineers, and produced security alarms and other equipment. You can watch the video here. In 2023, they invested in a fully automatic SMT production line at their new factory in Kazakhstan, which came with two JUKI chip mounters, greatly improving production efficiency, and matched with an automatic insertion line. It is used for the production of security products. You can read more about them here.

Our partner in Bulgaria established contact with us in 2018 and began long-term cooperation. Because the customer's factory workshop is limited, the SMT solution we provided to the customer, in addition to the basic fully automatic production line, also included a PCB Translation Shuttle Conveyor, which helps improve the efficiency, flexibility, and reliability of the production line.

Show a video for your reference