I.C.T Vacuum Reflow Soldering for Automotive Electronics

Min. Order : 1

Payment Type : L/C,T/T

Incoterm : FOB,CFR,CIF

Delivery Time : 45 working days

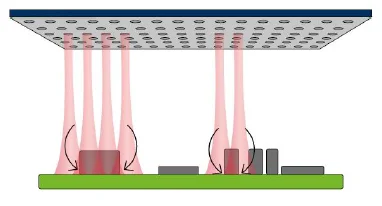

Brief introduction : Vacuum Reflow Soldering for Automotive Electronics I.C.T LV Series Vacuum reflow oven unparalleled heating performance and temperature control system meets the requirements of various soldering processes.