![]()

❙ Introduce of Energy-efficient Reflow Oven

High quality economic type reflow oven, reflow soldering oven, SMT reflow oven, reflow soldering machine, with 6 zones, 8 zones and 10 zones.

1. Control System

Computer or Instrument control, make sure machine working steadily.

2. Hot Air Heating System

Both top and bottom zones hot air heating, good heater compensatory,High thermal efficiency, energy saving, speedy heating, suitable for soldering components like BGA,CSP etc.Special forced hot air circulation structure makes PCB and components heat evenly, Temperature Accuracy ± 1.5 °C, room temperature settling time less than 20 minutes.

3. Cooling System

Independent cooling area ensures the low temperature when PCB comes out.

4. Transmission system

Use imported motors, speed adjuster, smoothly running, adjustable speed at 0-2000mm/min.

❙ Specifications of Reflow Oven

| Model | Lyra 622 |

Lyra 622N |

Lyra 732/ 733 |

Lyra 732N/ 733N |

| Quantity of preheating zones |

6 | 6 | 7 | 7 |

| Quantity of peak zones |

2 | 2 | 3 | 3 |

| Max. soldering temperature |

pre-heating zones 300 °C and peak zones350 °C |

|||

| Quantity of cooling zones |

2 | 2 | 2 | 3 |

| Mesh Width |

Standard 440mm( Option 560 & 680mm ) |

|||

| Rail Width |

Single Rail: 50 - 460mm, Option: 50 - 686mm other Width on request. Duo Rail Standard: 50 - 290mm*2 |

|||

| Dimensions |

5150*1400*1500mm |

5150*1400*1500mm |

5850*1400*1500mm |

6250*1400*1500mm |

| Weight |

2400 kg |

2600 kg |

2800 kg |

3000 kg |

| Model | L8 | L10 |

| Dimension (L*W*H)mm | 5000x1250x1490 | 5800x1250x1490 |

| Weight | Approx. 1600KG | Approx. 1800KG |

| Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 |

| Length Of Heating Zones | 3121mm | 3891mm |

| Rail Width Adjustment | M(option:A) | |

| Exhaust Volume | 10M3/minx2 Exhausts | |

| Control System | PLC+Computer | |

| Temperature Control Method | PID + SSR | |

| Transmission Agent | Chain + Mesh | |

| Electric Supply Required | 3 phase,380V 50/60Hz | |

| Power For Warm Up | 55KW | 64KW |

| Power Consumption | 8KW | 12KW |

| Warming Time | Approx.25 minute | |

| Temp. Setting Range | Room Temp.-- 300°C | |

| Conveyor Height | 900+/-20mm | |

| Conveyor Speed Range | 300~2000mm/mi | |

| Fixed Rail Side | Front Fixed (Option:Rear Fixed) | |

| Cooling Method | Forced-Air Motor and fan (Standard) |

|

| Model | T4 | T6 | T8 |

| Dimension (L*W*H)mm |

2000x890x1250 |

2500x890x1250 |

3100x890x1250 |

| Weight |

Approx.550KG |

Approx.850KG |

Approx.950KG |

| Number Of Heating Zones |

Up4/Bottom4 |

Up6/Bottom6 |

Up8/Bottom8 |

| Length Of Heating Zones |

980mm |

1550mm | 2100mm |

| Power For Warm Up |

20kw | 26kw | 30kw |

| Power Consumption |

5kw | 7kw | 9kw |

| Transmission Agent |

Mesh+Rail |

||

| Max.Width Of PCB |

300mm | ||

| Conveyor Height |

900+/-20mm | ||

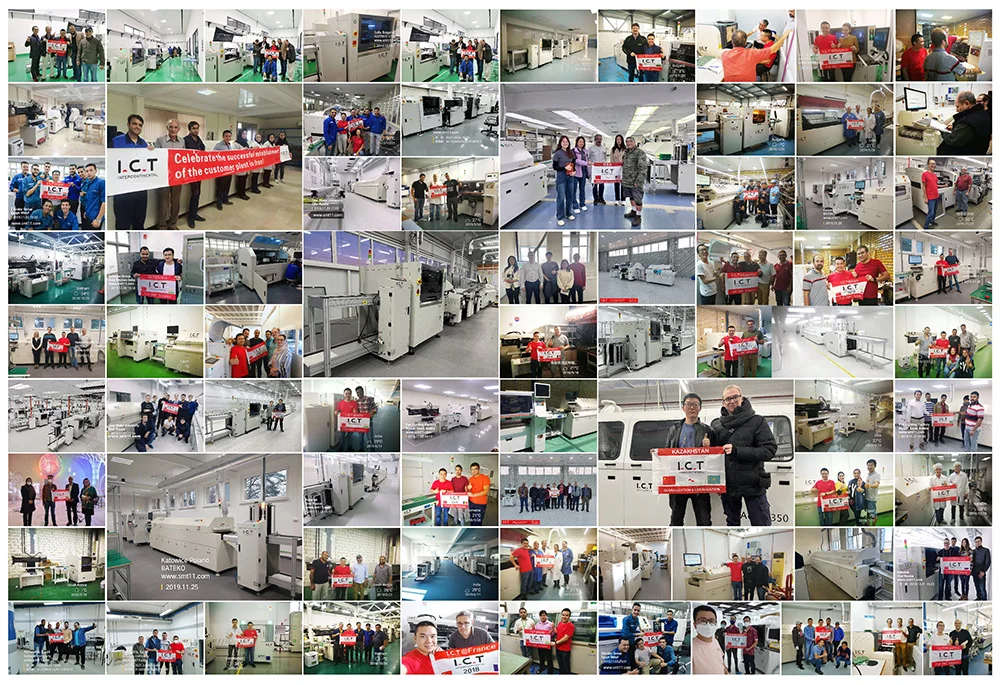

❙ I.C.T Customer Factory

❙ Company Profile

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT Production Line including SMT Stencil Printer, Pick and place machine, Reflow Oven, SMT AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Successful Experience:

I.C.T's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

❙ I.C.T SMT Machine Exhibition

❙ I.C.T Global Service

Welcome more people to discuss with us about SMT technologies and solutions, please Contact Us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat), Email: info@smt11.com / etasmt@foxmail.com

❙ Reflow Soldering Oven Video